1. Dilute phase pneumatic conveying

vacuum operation

2. Dilute phase pneumatic conveying pressure operation

3. Dilute phase pneumatic conveying pressure-vacuum operation

4. Dense phase pneumatic conveying pressure operation

Dense Phase

Dense Phase pneumatic transport-pneumatic conveying operation is used particularly for transfer of

aggressive and difficult materials. Sand, cement and glass industry

can be shown as example in this respect. Here, as the material is

aggressive it does not strike the pipe wall sharply, but moves

solidly by an air-product mix under high pressure of 2-5 bars and is

product to far distances. For example, bulk cement tankers operate

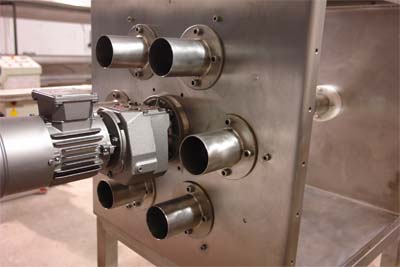

by this method. In this transfer method, unlike the fans with high

flow rate in the dilute phase, the screw compressors and

dehumidifiers at high flow rate are used.

High pressure air is delivered to the container full with the

product to be transferred and then the high pressure air-product mix

is transferred by the opening valve to the cyclone, silo or target

mixer. This method is used especially if there is material in the

process which may become fibrous or give damage to the

characteriStic of the product due to friction. The dense phase

operates with instruments different than those of the dilute phase

due to the transfer mechanism. The transport equipment are more

resistant compared to those of the dilute phase. In this transfer

performed by high pressure air, the thick-wall pipes and special

basalt elbows are used.

In the pneumatic transport- pneumatic conveying Centrifugal or Roots type blowers used as

air generators suck the air in the environment by vacuum and

develops thrust pressure by compressing the air. Due to relative

humidity of the air in the atmospheric environment, the water

particles serves as a good conductive during generation of the

pressure and, therefore, cause heating of the transfer air. This

temperature may occasionally reach up to 80oC depending on the

operating pressure of the process and drifting speed of the

transfer.

If the target transport material has a structure susceptible to

these temperatures, the operations of pre-cooling in the process and

final cooling before introduction of the air in the process may be

required. Because of the air temperature and speed, the most

appropriate solution may be Densifier, Transporter and Dense phase

transporter instead of complex structure of the dilute phase.

Click for Dense Phase Transfer Systems

Dilute Phase

Pneumatic transport-pneumatic conveying mostly preferred for granular and power

articles or products. The speed varies 12-25m/s depending on the

phase density of this transfer made by air. Transport method in the

pneumatic transfer is two types, namely dense phase and dilute phase.

Transfer operation in the dilute face is performed by vacuum or

pressure. The transport operation is generally performed in the

pressure range of 250-600mbar. These two methods should be

diStinguished depending on the process of these two methods.

Click for Dilute Phase Transfer Systems

(Vacuum, Pressure)-Blower

Mechanical Transport

Although the Mechanical Transport seems difficult and has a set of

patterns, it is the most cost-effective solution for electric power.

Investment cost is high in the long distances, but use of power is

less. In general, it is also used for transfer at fixed flow rate

volumetrically for all pneumatic transport operations.

Pneumatic transport-pneumatic conveying is the most flexible transport method compared

to the screw spiral, band and chain conveyor. Although many

secondary instruments and dust separation systems should operate

together, it is the most preferred transport system thanks to this

flexible structure.

Each product transported by air is first mixed with the air and then

separated from the air. Although both operations are difficult, it

is preferred due to its flexible structure.

While the mixing operation is performed by help of rotary valves,

loading stations and venture, the separation operation is performed

by means of filters. On the other hand, pneumatic means dust, dust

separation and absolute filtering.

Blowers are used as generator of air, the transport source; in other

words, the fans of low pressure high flow rate of air are used.

However it seems that the transport is performed by mixing process

pressure air with the product, it requires serious engineering

operation and experience. On the other hand, pressure and vacuum may

also be used in the pneumatic transport processes.

Each product to be transported pneumatically bears different

characteriStic. For this reason, density and efficient transport

pressure of each product differs. And this, in turn, differs ways of

transport. If you attempt to transport sugar on a line used for

transport of flour without any modification, your line is doomed to

fail as it may be expected normally. None of the equipment you use

may operate properly. If the process is designed correctly and it is

operated with proper instruments and equipment, you may transport

both sugar and flour on the same line after making parametric

changes in the automation system. This example shows necessity of a

serious infrastructure and concept of experience in the practice.

pneumatic conveying,pneumatic

conveyor,pneumatic transport,pneumatic conveying design, pneumatic

conveying, pneumatic conveying systems, pneumatic conveying system,

conveying powder, air filtration, vacuum conveying, dilute phase

conveying, continuous dense phase conveying, industrial air

filtration, hepa, high efficiency air filters, mac pulse jet air

filters, ventilation, airlock, rotary airlock, rotary valve,

material,pneumatic transport, management, bulk material handling,