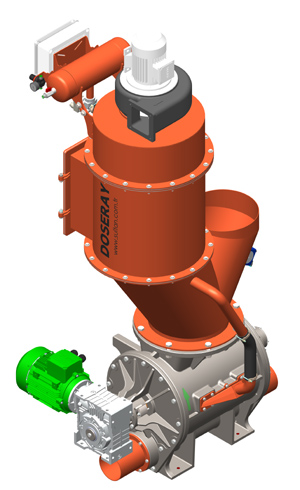

DUST FILTER ROTARY VALVE

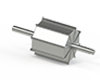

The use of rotary valves is a critical component for many dust collection processes. Rotary valves make it easier to control the flow of material from bins, hoppers, or silos, onto conveying or processing systems.

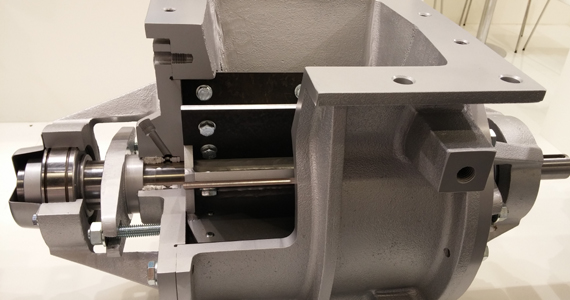

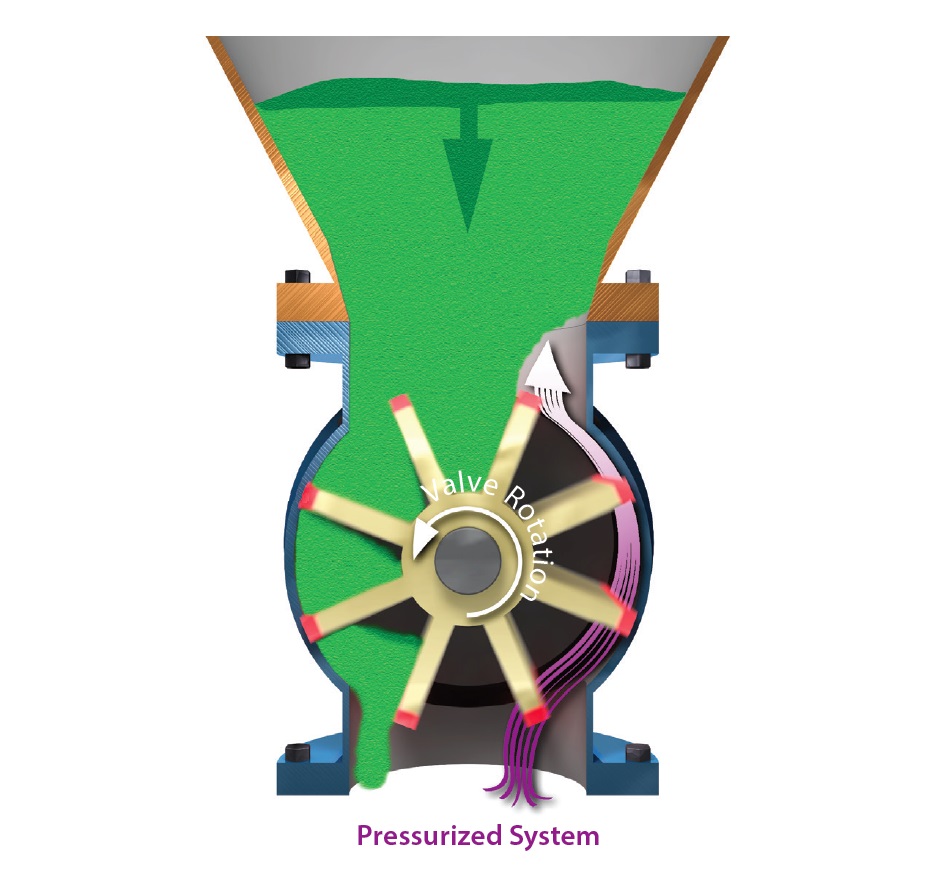

Rotary valves (also known as airlocks, rotary feeders, or airlock feeders) transition material from one pressurized point, such as a dust collector, to another unpressurized point, such as a drum or bin. The valve seals a pressurized system against loss of air and pressure. Rotary Valves help ensure loss of product during processing is minimized.

Typical dust collection applications for rotary airlocks are dust collection, pneumatic conveying, pollution control, mixing, feeding, weighing, drying, and blending. Some of the relevant industries for rotary airlocks include metalworking, cement, minerals, agriculture, wood, paper, rubber, textiles, grains, paint, pharmaceutical manufacturing, and many more.

How the AIRLOCK Rotary Valve Star Feeder Valve is Used?

When performing transfer on all pneumatic conveying lines, it is a device to feed the material down to the line and separate the raw material pneumatically transferred from the air. Blade forms, tolerances, revolution speeds vary depending on type of process and type of the product to be transported. Likewise, it may also act as breaker depending on the characteriStics of the material to be transported. Even it may also operate coupled with the breakers.Rotary Valve AIRLOCKs are designed for use under gravity,pressure and vacuum conditions.

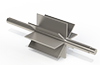

offset type pellet-granul Rotary Valve

The main feature of a Rotary Airlock is to regulate the flow of material from one chamber to another while maintaining a good airlock condition. The material or product being handled is usually dry free flowing powder, dust or granules.

The granule type of product, especially if it is a plaStic type, polythene or nylon etc., does not shear easily and consequently, without considerable care the standard drop-through type of valve leads to valve seizure and also considerable shock loadings.

To minimize these problems the Offset Rotary Airlock ensures lower pocket fillage as its design means that the rotor is Still being filled in the upward cycle with the pellets falling away at the shear point. Similarly, the pelican beak distributes the product across the full width of the rotor.

airlock body. This addition substantially reduces the amount of downtime and the number of man hours required for the cleaning and maintenance of the rotor and airlock internals.

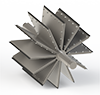

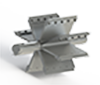

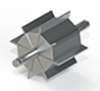

AIRLOCK, ROTARY VALVE - ROTOR TYPES

-

- Rotary Valve - Ailocks-Star Feeder internal Rotors have options such as blade, rounded type, adjusted blade type, stripper and polyamide.

Rotary Valve PDF brochure

Why Choose a DOSERAY Rotary AIRLOCK?

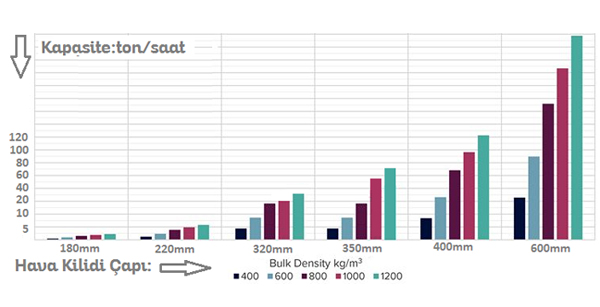

Air Filtration provides a complete line of rotary valve - AIRLOCKs

suitable for AIR LOCK applications ranging from gravity discharge

of filters, rotary valves, cyclone dust collectors, and rotary

valve - AIRLOCK storage devices to precision feeders for dilute

phase and continuous dense phase pneumatic conveying systems.

Rotary Valve / AIRLOCK Feeders are used in pneumatic conveying

systems, dust control equipment, and as volumetric feed-controls

to maintain an even flow of material through processing systems.

The basic use of the rotary valve, AIRLOCK feeder is as an AIRLOCK

transition point, sealing pressurized systems against loss of air

or gas while maintaining a flow of material between components

with different pressure. Rotary Valve, AIRLOCK Valves are also

widely used as volumetric feeders for metering materials at

precise flow rates from bins, hoppers, or silos onto conveying or

processing systems.

Blow ThrOUGH Rotary Valves

A rotary valve is of no use by itself. Rotary valve, AIRLOCKs are

useful as one component in a bulk or specialty material handling

system. Rotary Valve, AIRLOCK Feeders have wide application in

industry wherever dry free-flowing powders, granules, crystals, or

pellets are used. Typical materials include: cement, sugar,

minerals, grains, plaStics, dust, fly ash, flour, gypsum, lime,

coffee, cereals, pharmaceuticals, etc...

ROTARY VALVE AND PRODUCTS

Rotary AIRLOCK ( rotary valve) feeders have wide application in industry wherever dry free-flowing powders, granules, crystals, or pellets are used. Typical materials include: cement, ore, sugar, minerals, grains, plaStics, dust, fly ash, flour, gypsum, lime, coffee, cereals, pharmaceuticals, spray dryer, etc...

- Lebels: rotary valve, rotary AIRLOCK, AIRLOCK valve, rotary feeder, blow through rotary valve, flow through AIRLOCK, silo discharge, cyclone discharge, dust collection, pneumatic conveying, rotary AIR LOCK valve, rotary valve producer , rotary valve price, rotary valve draw