Sea Bulk Container Liners are the most efficient and economical means of packaging for dry, free flowing products from one country to another. Sea Bulk Container Liners are used inside 20', 30', 40', 40' High Cube Intermodal Containers, and 53' containers.

Essentially, we call this our "Silo to Silo Solution." One to two people can install and fill a container liner from rail car or silo within 1 hour, ship, and 1 person to discharge the product into your customer's warehouse silos.

This eliminates the needs for packing machines, man power to fill and move product to warehouse, packing into a container, unloading the container into storage warehouse, to final shipment to customer.

Sea Bulk Container Liners come in several forms whether a woven polyethylene bag or a PE Film to keep it safer from contamination. They are customizable for loading and unloading operations.

PDF

brochure

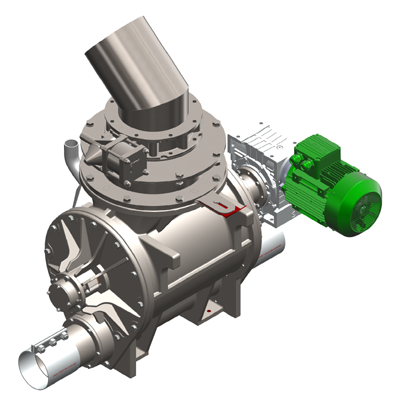

FOR FINE MATERIAL DISCHARGE

.

Silo to Silo Shipping Solutions"

Sea Bulk Container Liners are

meant for customers that can ship up to 55,000# of product into a

intermodal container for export from their site to their

customer's or consignee warehouse in another country.

Installation and Loading

1- One to two people sweep and

inspect the intermodal container for dust, sharp edges in the

container and nails. They secure the front (opposite doorway end)

with a securement bar or belt. After this, they tie the liners to

the lashes in the container until they get into the doorway end.

Last, they secure the bulk head to the container per the design

configuration. This entire operation takes less than 15 minutes

with experienced employees.

2 - The operator fill

the sea bulk container liner with air until it is fully inflated.

At this point whether shipping from rail car or silo (or even an

auger), the operators will fill the container liner with product

until it reaches its goal weight. The operators close off the

Loading Sleeves (or closes the zipper/duffel), shuts the door, and

it is ready for shipment. This can take from 10 minutes to 1.5

Hours depending on the loading equipment.

Discharging

3 - The operator will open 1 door of the

intermodal container, untie the discharge chutes (or cut the

bottom) and feeds into the pneumatic equipment to load the silo.

This takes less than 5 minutes.

4- The operator

will use a tilting chassis or platform and "tilt" the container in

10 degree increments up to 45 degrees. The worker can never get in

front of the doors once tilting occurs. As product slows in flow,

the operator will increase the angle of the container. This can

take anywhere between 30-60 minutes depending on the equipment.

5- When product stops flowing, the operator lowers the

container and opens the other door. The operator manipulate the

product to the discharge funnel. This takes less than 5 minutes.

6- Operator unhooks the container and removes the

container liner.

Dry Bulk Container Liners are a key component of the Bag-in-Box (BiB) method for transporting and storing dry bulk materials. The use of box containers for bulk logiStics provides a number of cost, quality and flexibility benefits over other forms of transport. Our liners form a clean, dry, protective shield between the product and the floor and walls of the container. This enables 20ft, 30ft and 40ft bulk containers to be used as a low cost alternative, not only to road tankers for the transport of dry bulk products, but also to intermediate bulk containers, bulk bags or big bags. After discharging, the container liner is simply removed and disposed of, leaving the container free of residue and the danger of cross-contaminating subsequent products. Significant manual handling costs can be avoided when moving from bags to bulk liners operations.

LINER BAG Discharge

Reduced costs

Protects products from contamination

Protects the

container from contamination

Seals out water and external

atmosphere

Easy to install, load and discharge

Tailored to all

filling and discharging systems

Highest quality performance and

reliability

Increased payloads

Reduced manual handling

- Lebels: Liner bag discharger, liner bag unload,Bulk truck unloading system, sea bulk container discharge ,container liner , bulk liner unloading system