BIGBAG DISCHARGE - FIBC Bag EmptIer - BIg bag UnloadeD

BIGBAG DISCHARGE STATION

Big bag discharge

stations are also known as big bag unloaders, bulk bag emptiers,

FIBC dischargers, FIBC unloaders, FIBC emptiers, super sack

dischargers, container bag unloaders, container bag dischargers,

super sack unloaders and super sack emptiers. Big bag emptying

stations let the user empty the material in any bigbag or super sack

and transfer it to another equipment like conveyor, mixer, silo etc.

Big bag unloading stations provide continuous and safe discharging

of big bags.They also prevent any harmfull dust spread to the

environment

Operating Principle of Big Bag Unloading Station

Big bag is brought to the carrier platform of the unit by the help

of forklift or built in hoist. The access door below the bag is

opened. The bag is untied or cut. Acess door is closed. The system

is ran from the control panel. The product in the big bag is

automatically discharged and transferred to the unit (conveyor,

rotary valve etc) connected to the station.

Advantages

-

Safe and clean working environment

- Dust free environment air

- Simple handling of bigbags

- Applicable for different

conveying and storage systems

- Wide range of models for

different applications

- Easy to clean

- Maintenance free

design

Features:

- Rigid, steel construction

-

Vibration motors and inclined hopper for better product flow

-

Access door and locking system for easier opening of bags.

-

Filter system for preventing dust.

- Hoist for better handling of

bigbags

Extra Options:

- Weighing and dosing system

- Food grade stainless steel construction

- Big bag cutting kit

used to cut the big bag as it is placed on the unit

- Pneumatic

activators to increase product flow rate

Discharging With

Pneumatic Conveying System

Bulk solids in the big bag is

transferred by pneumatic conveying system. It can be conveyed to

long distances by air pressure or vacuum. Equipments like silo,

container or mixer can be filled by pneumatic conveying system

connected to sack tip station. Bulk solid materials in powder and

granule form like plaStics, pvc, cement flour etc can be handled by

such kind of system.

Discharging With Screw Feeder

Bulk solids in the big bag is transferred by screw conveyor.

Equipments installed near the unit can be filled by screw feeder

connected to big bag emptying station. Bulk solid materials in

powder and granule form like plaStics, pvc, cement flour etc can be

handled by such kind of system.

PDF

brochure

FOR FINE MATERIAL BIG BAG DISCHARGE

.

WORKING PRINCIPLES OF BIGBAG

DISCHARGE STATION

BIG BAG DISCHARGE-FIBC Bag

Emptier-Big bag Unloader

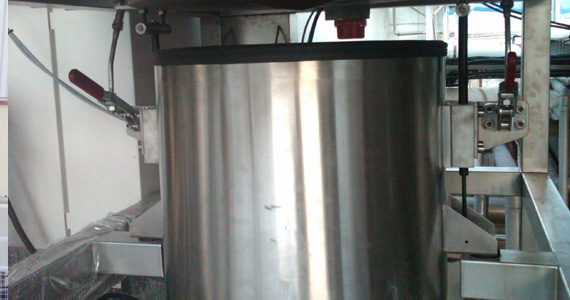

The basic station consists of:

- a

vibrating bottom.

- a discharge funnel.

- a heavy

stainles-steel frame.

TECHNICAL DATA FOR BIGBAG DISCHARGE-BIG

BAG UNLOADER

Material of construction: stainless steel, normal

mild steel

or combination of both.

Drive, vibrating bottom:

1 pcs. E-motor, P = 0,5 kW.

Capacity: approx. 6-8 Big-Bags/h.

(depending on product properties).

Dimensions of Bigbag

Discharge:1500x1500x5000mm

Max. height: 1000-1900 mm.

Max.

width: 1000 mm.

Max. length: 1000 mm.

Max. weight: 1500 kg.

Diameter outlet spout: 300 mm.

Length outlet spout: 500 mm