BIGBAG DISCHARGE - FIBC Bag EmptIer - BIg bag UnloadeD

BIGBAG DISCHARGE STATION

Powder or granular raw materials

are generally stored in the silos. And, on the other hand, if they

are delivered in big-bag sacks, the raw materials in the said

characteriStic are directed to the target location as appropriate

for pneumatic or screw (spiral).

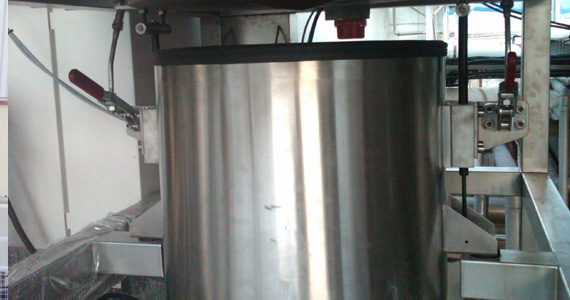

The basic station consists of:

- a vibrating bottom.

- a discharge funnel.

- a heavy stainles-steel frame.

The BigBag is attached to a hoist device for better handling. Following the hoist device with the BigBag is picked up by a hoist or a forklift and is manoeuvred over the vibrating bottom. The vibrating bottom is suspended in the heavy steel frame by means of spiral springs. A sideways mounted imbalance unit generates the vibrating action, to improve the product flow. The discharge funnel is integrated with the vibrating bottom and it is provided with a large access hatch to untie the outlet spout of the Big-Bag. Because the Big-Bag covers the funnel completely there is a closed system while discharging, which creates a dust-proof unit. The funnel is also provided with a flange-connection for a deduSting unit. The de-duSting also creates an air compensation while discharging. The heavy steel frame is a solid construction of completely closed and welded box profiles. In the funnel, beneath the access hatch, a screening-grid is mounted to intercept possible lumps and large pollutions. The grid is detachable.The right solution for Big Bags and sacks. Regardless of whether your raw materials are delivered in a sack, crate, Big Bag, bulk car or silo, the unloading and discharge process requires the greatest possible care and attention. Safety, quality and cost efficiency are paramount.

PDF

brochure

FOR FINE MATERIAL BIG BAG DISCHARGE

.

WORKING PRINCIPLES OF BIGBAG

DISCHARGE STATION

SWF(Inverter) brand, 2-ton capacity, 6m

chain, 4-action crane is attached to IPE 250 material on top of

the big-bag sacks stations. This crane advances forward, departing

from the main frame of the 1500 mm platform and comes forward to

lift the sack. Then the holding grabs of the sack are attached to

the hooks of the lifting cross and the sack is put to the

discharge cone with its mouth sealed by pneumatic cylinders. The

fastened inlet of the sack is unfastened. Then it is untied and

valve cylinders are opened within 1-10 scale according to the flow

status from the touch panel or the panel just near the operator.

When flow continues, the spiral conveyor or pneumatic transport

group connected to the inverter is enabled from the panel.

According to the flow condition, two vibrators in the station

start operate in interval. Thanks to these vibrators, both the

product in the big-bag sack falls down on the intermediate

collecting cone and the product in the intermediate collecting

cone falls on the conveyor. Configuration of the said vibrators,

pneumatic cylinders and spiral conveyors all are performed via the

touch panel.

Optionally, more than one station may be

connected adjacently and entire process may be displayed from a

single computer by SCADA

BigBag-Bulk Bag Discharge SELECTION

OF AVAILABLE OPTIONS:

- CLAMPING SYSTEM, to achieve a

dust-proof connection of the

outlet spout (very suitable for

hygienic applications and to form a

vacuum in the emptied

Big-Bag).

- DE-DUStiNG UNIT, multiple types and sizes

available, attuned to

the product.

- BigBag Discharge

System, metering screw conveyors,

slide or rotary valves.

-

CLOSED HOUSING/CHAMBER for toxic or very dusty powders.

-

POWDER DIVERTER VALVE, to avoid contamination of the

product by

dust/dirt at the outside of the Big-Bag.

- VACUUM

SUCTION/DISCHARGE OF RESTS, by connecting to a

pipe with

integrated control valves, there will be a vacuum on the

Big-Bag. In this way an efficient discharge of rests (no air/dust

contents) will result.

- Bigbag Discharge ROLL UP SYSTEM, for

empty Big-Bags and/or Inliner to be placed

separately or

directly on top of the discharge position.

- Bigbag Discharge

MODIFIED VIBRATING BOTTOM, to activate very bad-flowing

Products additionally.

- Bigbag Discharge FEEDING ROLLER

CONVEYOR (automatically), for Big-Bags on

pallets (incl. pallet

stacker).

- MOBILE UNIT.

- WEIGHING SYSTEM, to monitor the

product flow.

- EXPLOSION-PROOF DESIGN, according

ATEX-directives.

- CONTROL SIFTING, with our centrifugal sifter

machine.

TECHNICAL DATA FOR BIGBAG DISCHARGE-BIG BAG UNLOADER

Material of construction: stainless steel, normal mild steel

or

combination of both.

Drive, vibrating bottom: 1 pcs. E-motor, P

= 0,5 kW.

Capacity: approx. 6-8 Big-Bags/h.

(depending on

product properties).

Dimensions of Bigbag

Discharge:1500x1500x5000mm

Max. height: 1000-1900 mm.

Max.

width: 1000 mm.

Max. length: 1000 mm.

Max. weight: 1500 kg.

Diameter outlet spout: 300 mm.

Length outlet spout: 500 mm.

- Lebels: rotary valve, big bag unloader,bigbag discharger, big-bag emptying, bigbag station, bigbag emptying, bigbag dump station