How

the Airlock Rotary Valve Star Feeder Valve is

Used?

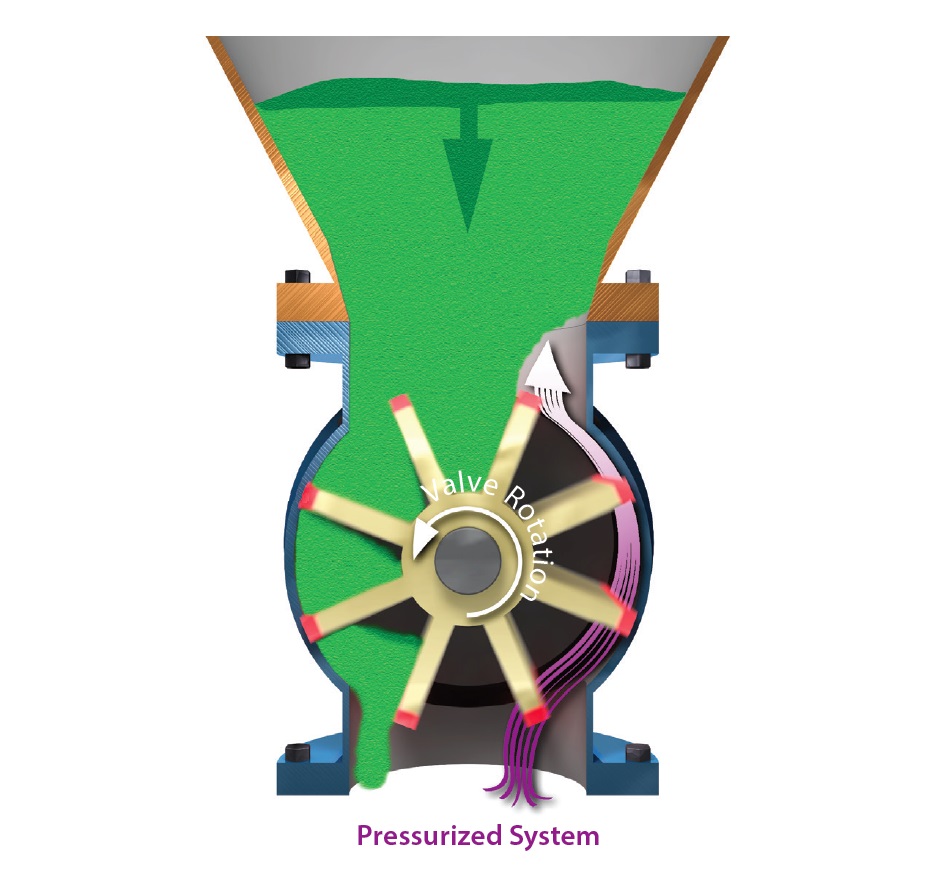

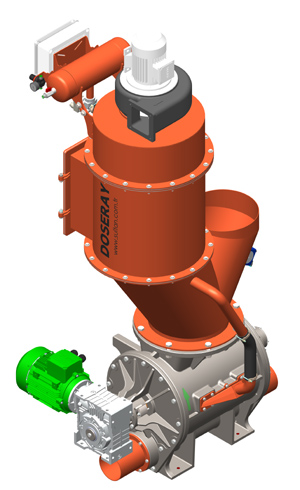

When performing transfer on all pneumatic conveying lines, it is a

device to feed the material down to the line and separate the raw

material pneumatically transferred from the air. Blade forms,

tolerances, revolution speeds vary depending on type of process and

type of the product to be transported. Likewise, it may also act as

breaker depending on the characteriStics of the material to be

transported. Even it may also operate coupled with the

breakers.Rotary Valve Airlocks are designed for use under

gravity,pressure and vacuum conditions.

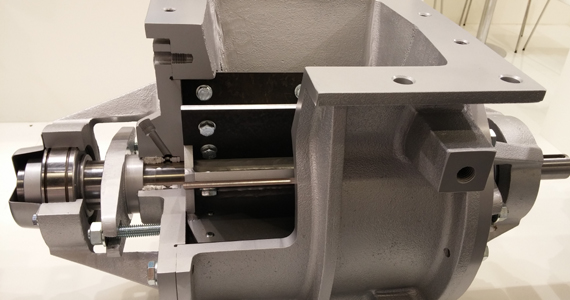

Rotary Valve - Airlocks - Star Feeder may be made of ST37 Carbon

Steel and AISI-304 AISI-316 Stainless Steel. Bedding types of the

air locks may be mechanical sealing and felt, again depending on the

hot process.

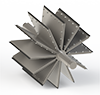

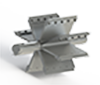

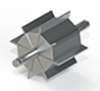

Rotary Valve - Ailock-Star Feeder internal Rotors have options such

as blade, rounded type, adjusted blade type, stripper and polyamide.

Rotary Valve - Airlock Star Feeder That the Cell Wheel has that

many options is completely related with type of material to be

transported as well as process. This is so vital that a single fault

may give damage to the material to be transported. Simple solution

commercially available may deliver successful results for transfer

of many materials such as flour, cement and many more. However, a

slight change in the granule size and a different material means

fail of such equipment.

Rotary Valve- Airlocks Function

Our Rotary Valves, designed according to a criteria of maximum applicative

universality, are suitable for controlled feeding or discharging of products in powder or

granular form, from silos, hoppers, pneumatic conveying systems, bag filters or cyclones.

ROTARY VALVE ROTOR TYPES

-

- Rotary Valve - Ailocks-Star Feeder internal Rotors have

options such as blade, rounded type, adjusted blade type,

stripper and polyamide. Discharging valve for

fine and coarse-grained products

Max. capacity through ideal ratio of rotor volume and inlet cross section

Special inlet geometry purpose-built for gentle product handling

With feeding show also suitable for feeding bulk materials into pneumatic conveying systems at up to 1.5 barg (21 psi)

PDF brochure

ROTARY VALVE APPLICATIONS

Air Filtration provides a complete line of rotary valve - airlocks suitable for air lock applications ranging from gravity discharge of filters, rotary valves, cyclone dust collectors, and rotary valve - airlock storage devices to precision feeders for dilute phase and continuous dense phase pneumatic conveying systems. Rotary Valve / Airlock Feeders are used in pneumatic conveying systems, dust control equipment, and as volumetric feed-controls to maintain an even flow of material through processing systems. The basic use of the rotary valve, airlock feeder is as an airlock transition point, sealing pressurized systems against loss of air or gas while maintaining a flow of material between components with different pressure. Rotary Valve, Airlock Valves are also widely used as volumetric feeders for metering materials at precise flow rates from bins, hoppers, or silos onto conveying or processing systems.

Drop Thru Rotary Valve Models

- 120mm DRAW- cad

- 180mm DRAW-cad

- 200mm DRAW valve -cad

- 220mm DRAW-Cad -cad

- 320mm Draw-cad

- 320mm Long Type Draw -cad

- 350mm Draw-cad

- 450mm Draw-cad

Blow Thru Rotary valve Models

While pneumatic transport processes differ according to the

phases, it may also diffrent in the same phase. Low pressure, that

is dilute phase transfer, can be categorized under 2 classes,

namely vacuum and pressure. This classification shows, even

slightly, differences in the rotary valve - airlocks.

Consequently, we perform manufactures according to the air locks

to be used on the vacuum and pressure line.

A rotary valve is of no use by itself. Rotary valve, airlocks are

useful as one component in a bulk or specialty material handling

system. Rotary Valve, Airlock Feeders have wide application in

industry wherever dry free-flowing powders, granules, crystals, or

pellets are used. Typical materials include: cement, sugar,

minerals, grains, plaStics, dust, fly ash, flour, gypsum, lime,

coffee, cereals, pharmaceuticals, etc...

While pneumatic transport processes differ according to the phases, it may also diffrent in the same phase. Low pressure, that is dilute phase transfer, can be categorized under 2 classes, namely vacuum and pressure. This classification shows, even slightly, differences in the rotary valve - airlocks. Consequently, we perform manufactures according to the air locks to be used on the vacuum and pressure line.

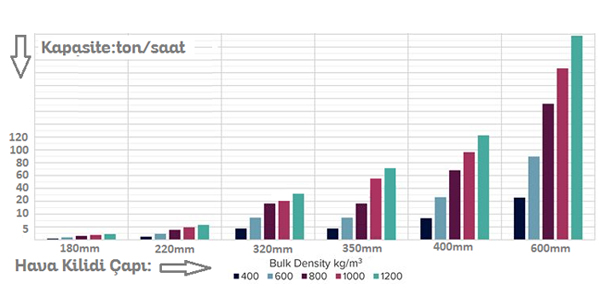

Rotary Valve Parts AND CAPACITY

Rotary airlock feeders have wide application in industry wherever dry

free-flowing

powders, granules, crystals, or pellets are used.

Typical materials include: cement,

ore, sugar, minerals, grains,

plaStics, dust, fly ash, flour, gypsum, lime, coffee,

cereals,

pharmaceuticals, etc...

- Lebels: label: rotary valve producer, airlock producer,pneumatic conveying rotary valve, conveying rotary valves,rotary valve seller,rotary valve type,steel rotary valve, hardox rotary valve,stainless steel rotary valve, rotary valve