MultIport Valve

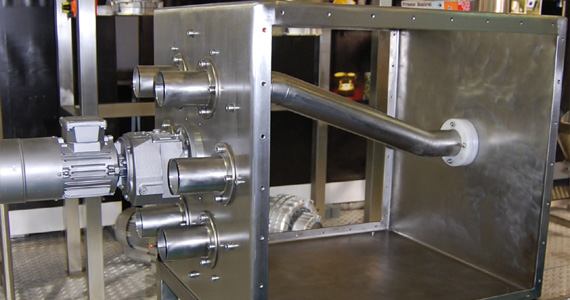

Rotary tube selector valves are used in powder pneumatic transport to divert product flow from single source to multiple deStinations. Flow can also be converged from multiple lines into one line. Multiport Rotary Tube selector valves are often used to replace a series of two-way valves, thereby simplifying the system, and reducing equipment footprint.

PNEUMATIC CONVEYING DIVERTER VALVES

Our Diverter Valve RangesDirectory of Diverter Valves , high performance diverter valves, single channel or double channel diverter valves, two way diverters, ball type diverters, diverting and selector valves, two way diverters, pneumatic line diverter, gravity and conveying diverters, and more ters, ball type diverters, diverting and selector valves, two way diverters, pneumatic line diverter, gravity and conveying diverter valves, and more

Pneumatic Diverter Valve Applications

It is used to send all kinds of powder material in granule form from one point to x number of different points particularly in the food industry as well as plaStics, pharmaceutics and chemical industries. We have two types of solutions, namely, 60.3,76.1,89,101mm and 114mm stainless AISI 304 inox and Aluminum Cast flap.Stainless Steel Diverter Valve for

Powders and Granular Products

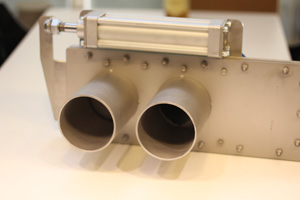

Single channel diverter valve in conical design for easier dismantling

Diverter Valves direct material from one source to multiple deStinations and make sure that conveying air and product are forwarded with low resistance

.

.

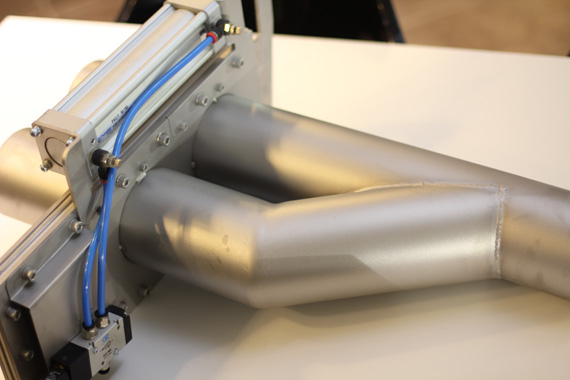

Diverter valve for pneumatic conveying applications

This precision machined valve is designed to prevent contamination

and provide line switching for either dilute or dense phase

conveying. The two-way DSR-DIVERT valve operates as a 1 to 2 way

diverting valve or a 2 to 1 way converging valve in a pneumatic

conveying system for powdered or granular materials.

The

DSR-DIVERT operates by rotating the tunnel forward and backwards in

the housing by the actuator. This positions the tunnel to either the

divert ports or the straight-through ports. The tunnel is supported

by shaft bearings in the two end plates and between two thrust

washers. The tunnel has position stops located in the housing for

fine adjustment of both conveying positions.

Tunnel position,

whether straight-through or divert, indication is made by two

proximity switches mounted in the housing, sensing directly off of

the tunnel. A positive seal is made through the selected position

between the tunnel bore and the housing interior by seal rings.

During tunnel position changes, the seal rings act like a wiper to

clean the surface of the tunnel.

Tunnel rotates 30° port to

port which prevents contamination

2-way switching capability for

either dilute or dense phase pneumatic conveying applications

Can

operate at convey line pressures up to 110 psi

Aluminum housing

and tunnel are hard anodized for wear resistance

-

Powders and Granular Products

Single channel diverter valve in conical design for easier dismantling

Diverter Valves direct material from one source to multiple deStinations and make sure that conveying air and product are forwarded with low resistance.

Choice of materials can cater for the majority of applications. Materials available are: cast iron, stainless steel, aluminium or chemically nickel plated. By coating the body and internal components mildly-abrasive products can be handled. Actuation can be handled manually or with pneumatic air cylinder (direct- or in-direct driven). All diverter valves can be executed with limit switches to indicate open/closed conditions. Flap type diverter valves are available in 8 sizes ranging from 50 up to 300 mm with circular connection flanges

PDF

brochure

MULTIPORT & DIVERTER VALVE

Multiport-Multi Way Valve-Diverter valve applications are used as automation and application provides comfort in terms fo follow-up when more than one two-directional valve proves to be insufficient. It works as sort of collector. However, single-directional valves acts like secondary roads departing from a motorway. Single handicap of the multiport applications is that if the process continues in the same direction, more pipes should be used; Still these two applications have different fields of use. It is possible to produce specific solutions for all pipes of AISI304 76.1mm and 114mm having one input and 4,6,8,10,12,14… outputs according to DN standard.

Benefits

• Easy cleaning

• Modular design

• Multiple installation options

• Parts interchangeable between

models

• No Motor Control Centre (MCC)

required

•

Visibility of internal components

(via three windows)

•

Designed to comply with

hygiene standards

Rotary Tube Selector Valves are used in

powder pneumatic transport to divert

product flow from single source to

multiple deStinations. Flow

can also be converged from multiple lines

into one line. Multiport Rotary Tube

Selector Valves are often used to replace a

series of twoway valves, thereby simplifying the system,

and reducing equipment footprint.

The DOSERAY Rotary Tube Selector Valve

brings a new level of innovation and

design to an integral component of a powder

conveying system. The enhanced structural

layout provides greater strength and

rigidity, allowing for regular and reliable

operation when changing powder

deStinations. The Rotary Tube Selector

Valve modular design is available in 2

through to 16

port versions with 3” to 6” pipe

configuration. Any of the

models can be hand demountable and is

manually cleanable.

Slıde gate dıveter valves

Compact form

• Optimal sealing

• Simple construction

•

Minimal pressure loss

• Available with flange or pipe fittings

•

Flanges drilled in accordance with PN10,

ANSI 150 lbs and JIS

•

Cast iron, aluminium or 316 stainless steel

- Lebels: pneumatic conveying valves, diverter valve, multiport valve

-

yön

klepesi, yönlendirme valfi, pnömatik yön klepesi, yön klapesi,

pnömatik klape imalatı, multiport uygulamaları, multiport,çok yollu

yön klapesi, pnömatik transfer yön valfi, yön klapesi, balık çiftlikleri için selektör valf

,pantalon klape, pantalon yön klapesi,pantalon klepe,çatal

vana,,pantalon klepe, pinch diverter valve, pinch yön klapesi,multiway

valve,multiport diverter valve, multiport pneumatic conveying

valve, pneumatic conveying valve, multi-port valve,Two-way

diverter valves for pneumatic conveying, rotary tube selector

valve, rotary multi way valve